In the industrial world, machinery and assets are the lifelines that keep everything running. But like any living system, these assets require care, timing, and precision. Think of it like tending a garden—you can’t water the plants too early or too late. Prescriptive maintenance follows this same logic. It doesn’t just react when something breaks; it predicts and prescribes the right actions at the right time using data-driven models.

This is where optimisation enters the scene—a way to turn the chaos of maintenance schedules into a disciplined rhythm that saves both money and downtime.

The Shift from Reactive to Prescriptive Maintenance

For decades, maintenance strategies evolved slowly. Reactive maintenance waited for a failure to happen, while preventive maintenance followed a fixed schedule—sometimes wasting effort on equipment that didn’t need it yet. Prescriptive maintenance, however, takes a step further.

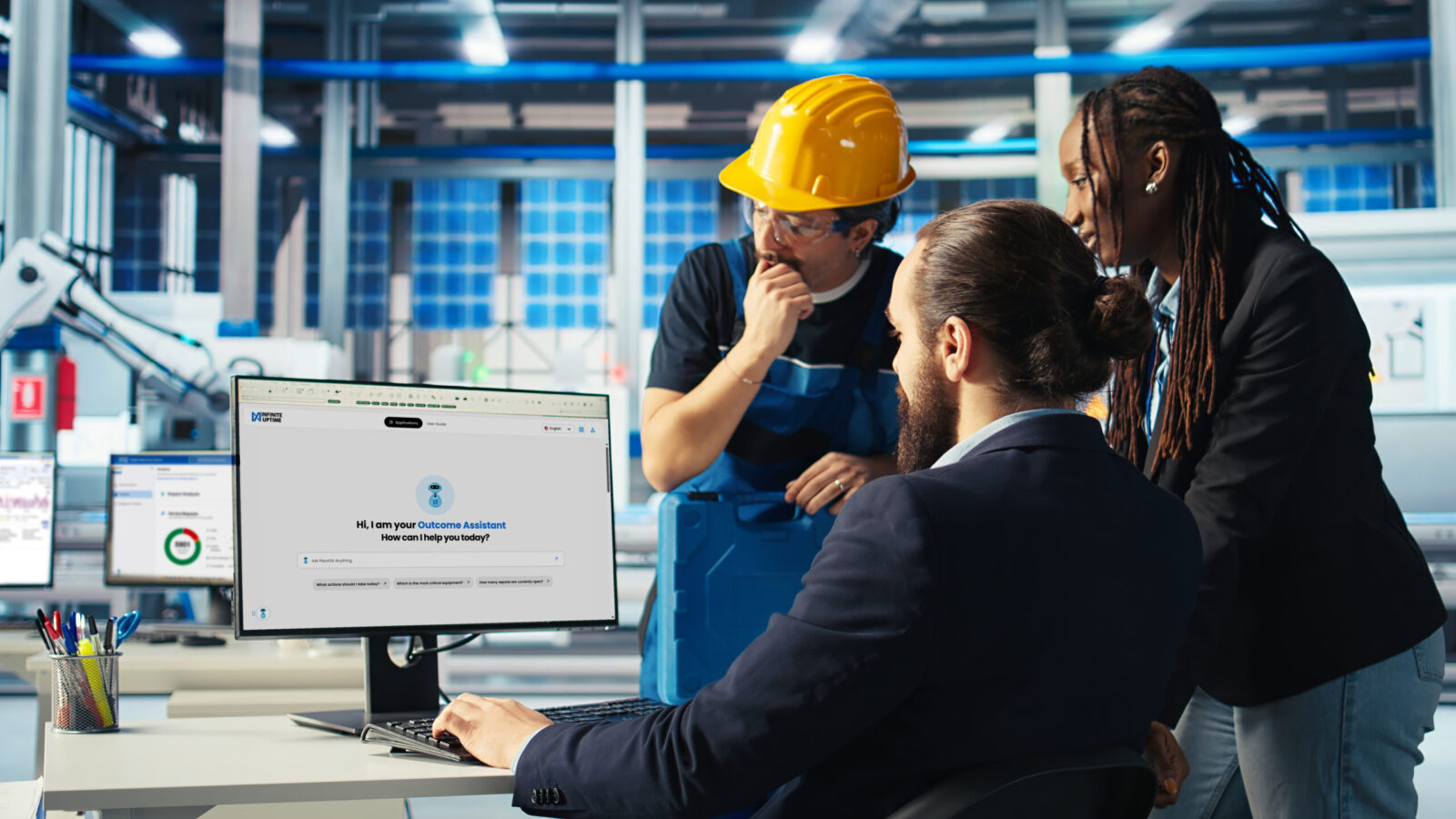

Using analytics, sensors, and machine learning, it not only predicts failures but also recommends the best course of action to prevent them. The result? Fewer surprises, less downtime, and smarter allocation of resources.

Professionals enrolling in business analyst coaching in Hyderabad often study these predictive-to-prescriptive transitions as a model for data-driven decision-making. It mirrors how business analysts optimise systems—anticipating problems before they emerge.

Data: The Fuel Behind Optimisation

Prescriptive maintenance thrives on one thing—data. Streams of information from sensors, performance logs, temperature readings, and vibration patterns help algorithms identify when a component is deviating from its healthy state.

But raw data alone isn’t enough. The magic lies in transforming that data into actionable insights. Machine learning models simulate different maintenance scenarios, testing what would happen if repairs were delayed, advanced, or combined with other tasks. This process helps determine the most cost-effective and least disruptive maintenance plan.

Just as a doctor analyses multiple symptoms before prescribing treatment, these models ensure maintenance decisions are grounded in accurate diagnosis rather than guesswork.

Optimisation Models: Finding the Sweet Spot

The heart of prescriptive maintenance lies in optimisation models. These models balance conflicting objectives—minimising downtime, reducing maintenance costs, and maximising equipment lifespan.

Linear programming, mixed-integer optimisation, and heuristic algorithms are commonly used to achieve this balance. They evaluate countless possibilities to answer key questions:

- Which assets should be maintained first?

- How can maintenance tasks be grouped efficiently?

- What is the ideal time to service each machine without halting production?

By combining probability with cost-benefit analysis, prescriptive models ensure every maintenance decision adds measurable value.

Real-World Implementation and Benefits

Industries such as aviation, energy, and manufacturing are already using prescriptive maintenance to great success. Airlines, for instance, rely on real-time aircraft data to decide whether a part needs attention after each flight. Manufacturing plants use predictive models to time their maintenance windows between production cycles.

For aspiring professionals, understanding these optimisation strategies is crucial. Courses like business analyst coaching in Hyderabad bridge this gap—showing how data interpretation, statistical modelling, and domain knowledge come together to drive real-world value.

The practical results are remarkable: reduced operational costs, improved asset reliability, and fewer production interruptions. Companies not only maintain performance but also enhance it continuously through data feedback loops.

Overcoming the Challenges

Despite its advantages, prescriptive maintenance is not without hurdles. Setting up reliable data pipelines and maintaining data quality can be difficult. Many organisations struggle with integrating disparate systems—each producing its own form of data.

Another challenge is cultural. Maintenance teams must adapt from intuition-based decisions to model-based reasoning. This transition requires not just technical tools but also training and leadership support.

The good news is that as technologies mature, these barriers are lowering. Cloud computing, IoT integration, and accessible analytics platforms have made prescriptive maintenance more achievable than ever.

Conclusion

Prescriptive maintenance marks a revolutionary step forward in asset management. By using optimisation models to predict and prescribe actions, organisations can move from reactive firefighting to proactive control.

In this new era, data doesn’t just monitor—it advises. It turns every machine into a storyteller, sharing insights about when and how it needs attention.

For professionals seeking to contribute to this transformation, learning to interpret and optimise data-driven decisions is invaluable. Mastery begins with curiosity and grows through structured learning—ultimately leading to a future where every maintenance move is not a reaction, but a well-timed, optimised decision.